- HOME

-

PRODUCTS

Extraction Distillation Equipment Reactor Rotary Evaporator Bioreactor Fermenter Freeze Dryer Spray Dryer Steam Sterilizer Centrifuge Lab Furnace Drying Oven Incubator Low Temperature Freezer Laboratory Equipment Life Science Instrument Drug Testing Instrument Food Testing Instrument Analytical Instrument Petroleum Testing Equipment Water Analysis Instrument

- SOLUTION

- NEWS

- SUPPORT

- VIDEOS

- ABOUT

- CONTACT

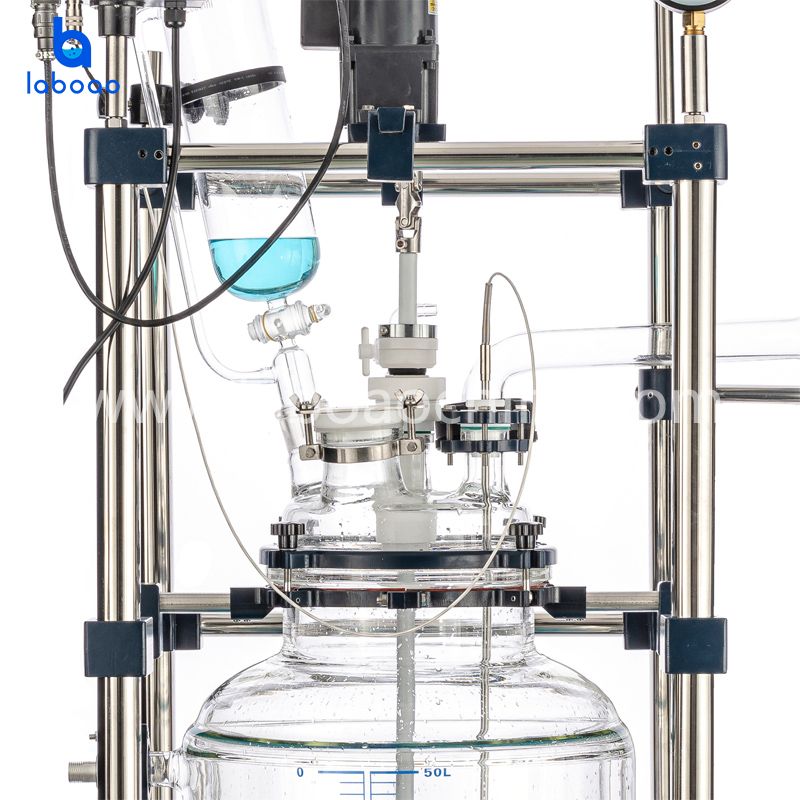

Reactor

Application

-

Chemical SynthesisEsterification - Glass reactors are used for synthesizing esters, which find applications in perfumes, flavors, and pharmaceuticals. Hydrogenation - They facilitate hydrogenation reactions, such as the reduction of unsaturated compounds to saturated ones. Condensation - Glass reactors aid in condensation reactions to form new compounds, such as the formation of amides or ester linkages.

Chemical SynthesisEsterification - Glass reactors are used for synthesizing esters, which find applications in perfumes, flavors, and pharmaceuticals. Hydrogenation - They facilitate hydrogenation reactions, such as the reduction of unsaturated compounds to saturated ones. Condensation - Glass reactors aid in condensation reactions to form new compounds, such as the formation of amides or ester linkages. -

Pharmaceutical ProductionAPI Synthesis - Glass reactors are employed in the synthesis of Active Pharmaceutical Ingredients (APIs) for drug production. Crystallization - They enable controlled crystallization of pharmaceutical compounds to obtain pure and well-defined crystals. Drug Formulation - Glass reactors are used in the formulation and optimization of drug delivery systems, such as liposomes or nanoparticles.

Pharmaceutical ProductionAPI Synthesis - Glass reactors are employed in the synthesis of Active Pharmaceutical Ingredients (APIs) for drug production. Crystallization - They enable controlled crystallization of pharmaceutical compounds to obtain pure and well-defined crystals. Drug Formulation - Glass reactors are used in the formulation and optimization of drug delivery systems, such as liposomes or nanoparticles. -

Petrochemical IndustryCatalytic Reactions - Glass reactors facilitate catalytic reactions, including those involved in petroleum refining and production of chemicals. Distillation - They are used in distillation processes for separating and purifying different components of petroleum products.

Petrochemical IndustryCatalytic Reactions - Glass reactors facilitate catalytic reactions, including those involved in petroleum refining and production of chemicals. Distillation - They are used in distillation processes for separating and purifying different components of petroleum products. -

Material ScienceNanomaterial Synthesis - Glass reactors aid in the synthesis of nanoparticles, nanotubes, and other nanomaterials with precise control over their properties. Sol-Gel Processes - They are utilized in sol-gel processes to create materials with controlled porosity and composition, such as thin films or coatings.

Material ScienceNanomaterial Synthesis - Glass reactors aid in the synthesis of nanoparticles, nanotubes, and other nanomaterials with precise control over their properties. Sol-Gel Processes - They are utilized in sol-gel processes to create materials with controlled porosity and composition, such as thin films or coatings. -

Material ScienceFermentation - Glass reactors are used in the fermentation process for the production of alcoholic beverages, yogurt, and other fermented food products. Flavor and Fragrance Extraction - They facilitate the extraction of flavors and fragrances from natural sources using solvents and distillation techniques.

Material ScienceFermentation - Glass reactors are used in the fermentation process for the production of alcoholic beverages, yogurt, and other fermented food products. Flavor and Fragrance Extraction - They facilitate the extraction of flavors and fragrances from natural sources using solvents and distillation techniques. -

Food and Beverage IndustryWater and Wastewater Treatment - Glass reactors aid in studying and optimizing water treatment processes, such as oxidation, disinfection, or removal of pollutants. Air Pollution Monitoring - They are utilized in environmental research to simulate atmospheric conditions and analyze air pollutants.

Food and Beverage IndustryWater and Wastewater Treatment - Glass reactors aid in studying and optimizing water treatment processes, such as oxidation, disinfection, or removal of pollutants. Air Pollution Monitoring - They are utilized in environmental research to simulate atmospheric conditions and analyze air pollutants. -

Environmental AnalysisChemical Kinetics - Glass reactors enable the study of reaction rates, mechanisms, and kinetic parameters for various chemical systems. Photocatalysis - They are used to investigate photocatalytic reactions, such as the degradation of pollutants using light and catalysts.

Environmental AnalysisChemical Kinetics - Glass reactors enable the study of reaction rates, mechanisms, and kinetic parameters for various chemical systems. Photocatalysis - They are used to investigate photocatalytic reactions, such as the degradation of pollutants using light and catalysts. -

Academic ResearchBioreactor Systems - Glass reactors with suitable accessories are employed in bioreactor systems for cell culture, fermentation, and bioprocessing. Enzyme Immobilization - They aid in the immobilization of enzymes for various applications, such as biocatalysis or biosensors.

Academic ResearchBioreactor Systems - Glass reactors with suitable accessories are employed in bioreactor systems for cell culture, fermentation, and bioprocessing. Enzyme Immobilization - They aid in the immobilization of enzymes for various applications, such as biocatalysis or biosensors.

FAQ

- What types of reactors are there?

- Single-layer glass reaction kettle, double-layer glass reaction kettle, triple-layer glass reaction kettle, crystallization reaction kettle, lifting reaction kettle, stainless steel reaction kettle, the above types can be customized to explosion-proof reaction kettle (optional).

- What are the capacities of glass reactors?

- Our glass reactors are available in 1L, 2L, 3L, 5L, 10L, 20L, 30L, 50L, 100L, 150L, 200L (maximum capacity).

- What are the common supporting equipment for reactors?

- The double-layer reactor can be equipped with high and low temperature pumps, high temperature oil baths, cryogenic pumps and vacuum pumps. The single-layer reactor can be equipped with cryogenic pumps and vacuum pumps.

- 4.What is the difference between single, double and triple layer glass reactors?

- Single-layer glass reactor consists of a single-layer glass container. It is often used for simple chemical reactions, such as stirring, heating and cooling of solutions, and is widely used in laboratory research and small-scale production. The double-layer glass reactor is composed of two glass containers. The inner container is used for the mixing and reaction process of the reactants, while the outer container is used for heating and coolant circulation, which can better control the reaction temperature and maintain a constant Reaction conditions. The triple-layer glass reactor is composed of three-layer glass containers. It is based on the double-layer glass reactor and adds a layer of glass container for vacuuming. It can keep the materials in the kettle as cool as possible under the vacuum state of the outermost layer. or heating temperature. Double-layer and triple-layer glass reactors are widely used in medium and large-scale production in pharmaceutical, chemical, food and other fields.

- What is the maximum pressure resistance of a glass reactor?

- Jacket pressure: maximum 0.04Mpa, which is 0.4kg positive pressure. The glass kettle body is not resistant to positive pressure.

- Will the cryogenic pump pressure damage the glass reactor?

- The circulating pressure of the cryogenic pump is 0.2Mpa. Because it is cyclic, the pressure is directly pumped out and will not damage the glass reactor.

- Can PH be measured in a glass reactor?

- It can be customized, and the PH port can be increased by covering the glass reactor above 5L.

- What are the shapes of the stirring paddles of glass reactors?

- There are anchor paddles, inclined blade paddles, propeller paddles or frame paddles for mixing. The choice of the form of the stirring paddle depends on the aggregation state of the materials in the kettle, the viscosity of the materials, the amount of the materials, and the ratio of the gas, liquid, and solid phases. At present, the stirring paddles of glass reactors are mostly made of polytetrafluoroethylene (easy to clean and will not pollute materials) and stainless steel.

- What are the advantages of glass lifting reactor?

- The glass lifting reaction kettle makes it more convenient to observe the reaction process. The height and angle of the reaction kettle can be adjusted as needed, improving the flexibility and efficiency of the experiment.

- How to speed up the heating rate of glass reactor?

- 1. Choose special thermal insulation cotton to wrap the double-layer glass reactor to achieve a thermal insulation effect, which can effectively prevent excessive temperature loss and increase the heating speed. 2. Appropriately increase the set temperature of the high-temperature oil bath (high-temperature circulator) so that the reactor can accept a higher temperature and shorten the heating time. When the reactivity of the double-layer glass is close to the use temperature, lower the temperature of the high-temperature oil bath (high-temperature circulator) to the actual use temperature. 3. Add the solution in the glass reaction kettle in batches. Do not fill it up all at once. This will affect the heating rate. Each time the solution is added, it is about one-half of the capacity. After the temperature rises to close to the set temperature, add more liquid into the kettle. Adding materials can also increase the heating rate!

- What is the difference between glass reactor and stainless steel reactor?

- Glass reactors are more suitable for chemical synthesis experiments of strong acids and alkalis, but can only withstand negative pressure. Stainless steel reactors can withstand negative pressure and a certain positive pressure, with a greater stirring torque and better stirring effect for viscous materials. The disadvantage is that they have poor resistance to strong acids and alkalis.

- How to use jacketed glass reactor with circulating pump?

- When reacting under normal temperature and negative pressure conditions, it is recommended that jacketed glass reactor be used with circulating water vacuum pump. When reacting under low temperature and negative pressure conditions, it is recommended that jacketed glass reactor be used with low temperature coolant circulation pump and circulating water vacuum pump. When reacting under high temperature and normal pressure conditions, it is recommended that jacketed glass reactor be used with a high temperature circulating oil bath. When reacting under negative pressure conditions within an ultra-wide temperature range, it is recommended that jacketed glass reactor be used with heater chiller circulation device and circulating water vacuum pump. When reacting under negative pressure conditions within an ultra-wide temperature range and there is a need to collect coolant, it is recommended that jacketed glass reactor be used with heater chiller circulation device, low temperature coolant circulation pump, and circulating water vacuum pump.

Related Article

-

Laboratory glass reactor using installation steps

The glass reactor commonly used in the laboratory passes through the reaction vessel interlayer, injects a constant temperature (high temperature or low temperature) hot-dissolving medium or a cooling medium, and the material in the reaction kettle is heated or cooled at a constant temperature, and stirring can be provided. The material is reacted in the reaction kettle, and the evaporation and reflux of the reaction solution can be controlled. After the reaction is completed, the material can be discharged from the discharge port of the bottom of the kettle, and the operation is convenient. It is an ideal equipment for modern chemical samples, sample experiments, biopharmaceuticals and new materials.

-

What are the advantages of an explosion proof jacketed glass reactor compared to a conventional reactor?

There are many kinds of reactors including single layer glass reactors, jacketed glass reactors, explosion proof jacketed glass reactors, etc. However, jacketed glass reactors are widely used, and explosion proof jacketed glass reactors are passed through jacketed reactors. The interlayer is injected with a constant temperature (high temperature or low temperature) hot solution or coolant, and the material in the reactor is heated or cooled at a constant temperature, and stirring can be provided.

-

Double layer glass reactor daily maintenance method

The glass reactor is an ideal pilot and production equipment for the synthesis of modern fine chemicals, biopharmaceuticals and new materials. The inner layer container of the double-layer glass reactor is placed with the reaction material, and at the same time, vacuum and speed stirring can be performed, and the interlayer can be introduced into the freezing liquid, water or high temperature liquid to heat and cool the material. It is used in experiments, pilot tests and production of chemical, fine chemical, biopharmaceutical new material synthesis. The product can be combined with circulating water vacuum pump, diaphragm vacuum pump, low temperature coolant circulating pump, high and low temperature integrated machine to form a system device.