- HOME

-

PRODUCTS

Extraction Distillation Equipment Reactor Rotary Evaporator Bioreactor Fermenter Freeze Dryer Spray Dryer Steam Sterilizer Centrifuge Lab Furnace Drying Oven Incubator Low Temperature Freezer Laboratory Equipment Life Science Instrument Drug Testing Instrument Food Testing Instrument Analytical Instrument Petroleum Testing Equipment Water Analysis Instrument

- SOLUTION

- NEWS

- SUPPORT

- VIDEOS

- ABOUT

- CONTACT

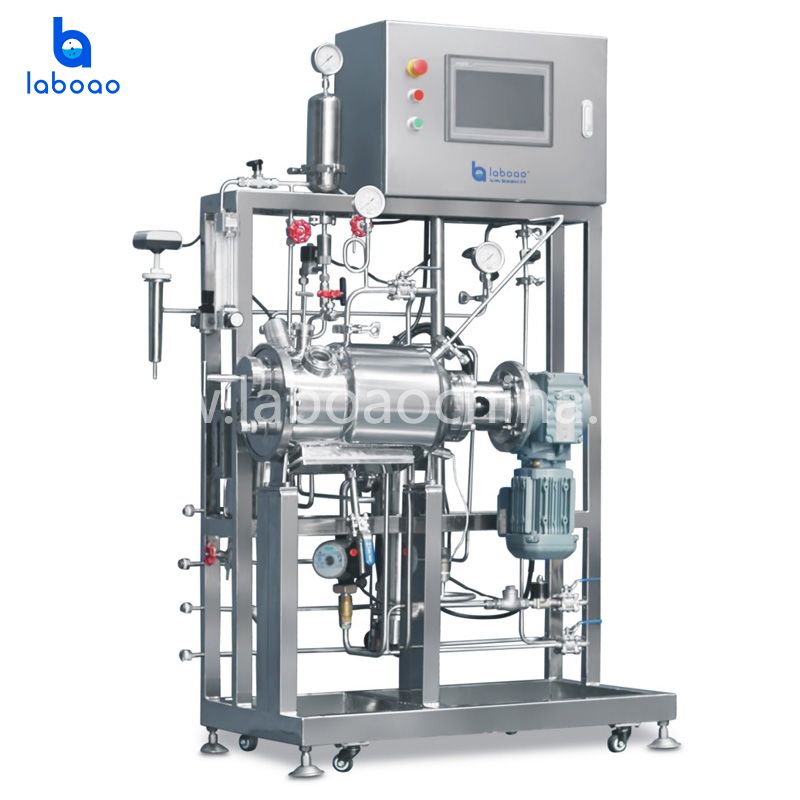

Bioreactor Fermenter

Application

-

Microbial FermentationIndustrial Enzyme Production - Bioreactor fermenters are used for large-scale cultivation of microorganisms to produce enzymes for industrial applications, such as detergent production or food processing. Antibiotic Production - They aid in the cultivation of antibiotic-producing microorganisms, enabling the large-scale production of antibiotics for medical use.

Microbial FermentationIndustrial Enzyme Production - Bioreactor fermenters are used for large-scale cultivation of microorganisms to produce enzymes for industrial applications, such as detergent production or food processing. Antibiotic Production - They aid in the cultivation of antibiotic-producing microorganisms, enabling the large-scale production of antibiotics for medical use. -

BiopharmaceuticalsRecombinant Protein Production - Bioreactor fermenters facilitate the cultivation of genetically engineered cells to produce therapeutic proteins, such as insulin or monoclonal antibodies. Vaccine Production - They are utilized for the large-scale production of vaccines by growing cells or microorganisms that express vaccine antigens.

BiopharmaceuticalsRecombinant Protein Production - Bioreactor fermenters facilitate the cultivation of genetically engineered cells to produce therapeutic proteins, such as insulin or monoclonal antibodies. Vaccine Production - They are utilized for the large-scale production of vaccines by growing cells or microorganisms that express vaccine antigens. -

Tissue EngineeringScaffold Seeding - Bioreactor fermenters aid in the seeding of cells onto three-dimensional scaffolds, enabling the growth and development of tissue-engineered constructs for regenerative medicine. Cell Expansion - They facilitate the expansion and proliferation of cells in a controlled environment, necessary for tissue engineering and cell-based therapies.

Tissue EngineeringScaffold Seeding - Bioreactor fermenters aid in the seeding of cells onto three-dimensional scaffolds, enabling the growth and development of tissue-engineered constructs for regenerative medicine. Cell Expansion - They facilitate the expansion and proliferation of cells in a controlled environment, necessary for tissue engineering and cell-based therapies. -

Algal BiotechnologyBiofuel Production - Bioreactor fermenters are used for the cultivation of algae to produce biofuels, such as biodiesel or bioethanol. Nutraceuticals and Bioproducts - They aid in the large-scale cultivation of algae to obtain valuable compounds like omega-3 fatty acids or pigments for use in food, cosmetics, or pharmaceuticals.

Algal BiotechnologyBiofuel Production - Bioreactor fermenters are used for the cultivation of algae to produce biofuels, such as biodiesel or bioethanol. Nutraceuticals and Bioproducts - They aid in the large-scale cultivation of algae to obtain valuable compounds like omega-3 fatty acids or pigments for use in food, cosmetics, or pharmaceuticals. -

Environmental ApplicationsWastewater Treatment - Bioreactor fermenters facilitate the growth of microorganisms for the biological treatment of wastewater, allowing the removal of pollutants and organic compounds. Bioremediation - They aid in the cultivation of microorganisms capable of degrading or detoxifying environmental pollutants, contributing to the cleanup of contaminated sites.

Environmental ApplicationsWastewater Treatment - Bioreactor fermenters facilitate the growth of microorganisms for the biological treatment of wastewater, allowing the removal of pollutants and organic compounds. Bioremediation - They aid in the cultivation of microorganisms capable of degrading or detoxifying environmental pollutants, contributing to the cleanup of contaminated sites. -

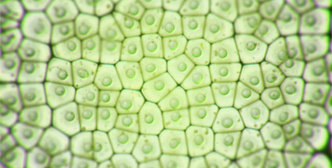

Agricultural BiotechnologyPlant Cell Culture - Bioreactor fermenters are utilized for the large-scale cultivation of plant cells to produce secondary metabolites, such as pharmaceuticals or flavors. Micropropagation - They aid in the rapid multiplication and propagation of plant tissues in a controlled environment for plant breeding or commercial plant production.

Agricultural BiotechnologyPlant Cell Culture - Bioreactor fermenters are utilized for the large-scale cultivation of plant cells to produce secondary metabolites, such as pharmaceuticals or flavors. Micropropagation - They aid in the rapid multiplication and propagation of plant tissues in a controlled environment for plant breeding or commercial plant production. -

Biofuels and Renewable EnergyBioethanol Production - Bioreactor fermenters are used for the fermentation of biomass-derived sugars to produce bioethanol as an alternative fuel source. Biogas Generation - They aid in the anaerobic fermentation of organic waste to produce biogas, which can be used for heat, electricity, or fuel production.

Biofuels and Renewable EnergyBioethanol Production - Bioreactor fermenters are used for the fermentation of biomass-derived sugars to produce bioethanol as an alternative fuel source. Biogas Generation - They aid in the anaerobic fermentation of organic waste to produce biogas, which can be used for heat, electricity, or fuel production. -

Food and Beverage IndustryFermented Food Production - Bioreactor fermenters are utilized for large-scale production of fermented foods and beverages, such as yogurt, cheese, beer, or wine. Single-Cell Protein Production - They facilitate the cultivation of microorganisms as a protein source for food and feed applications, offering a sustainable protein alternative.

Food and Beverage IndustryFermented Food Production - Bioreactor fermenters are utilized for large-scale production of fermented foods and beverages, such as yogurt, cheese, beer, or wine. Single-Cell Protein Production - They facilitate the cultivation of microorganisms as a protein source for food and feed applications, offering a sustainable protein alternative.

FAQ

- What kind of bioreactor fermenter do you have?

- Glass bioreactor, light bioreactor, stainless steel fermenter, airlift fermenter, solid state fermenter, multi-stage fermenter, parallel fermenter etc.

- How many liters are available for glass bioreactor?

- If used for bacterial culture, 0.5L-15L are available. If used for cell culture, 0.5L~40L are available.

- What is the tank capacity of the stainless steel fermentater system?

- We can produce 5L~10000L stainless steel fermentater, tank capacity can be OEM.

- What is the brand for sensor and probe?

- PH/DO sensor is Hamilton or Mettler brand.

- What is the optional configuration for the fermenter?

- Thermal mass flow controller (TMFC), automatic air intake, automatic pressure control, automatic sterilization (SIP), live cell detection, turbidity detection, GMP standard, feed balance weighing, tank weighing, online detection (ethanol) alcohol and CO2 content, automatic can lid lifting function etc.

- What equipment is needed to use a bioreactor?

- Air compressor, Circulating chiller, Seed tank, Supply tank, CIP etc. Depends on requirements during fermentation.

- What is a CIP system?

- "CIP" is the abbreviation of Clean In Place, which means cleaning in place. CIP cleaning systems are widely used in the cleaning and purification of production equipment with strict hygiene requirements in the beverage, dairy, juice, alcohol, and pharmaceutical industries, including containers, tanks, pipes, pumps, filters, etc. The CIP cleaning unit consists of a high-pressure cleaning pump, cleaning spray balls, and electrical control cabinets. We can provide fixed or mobile single-tank, double-tank or multi- tank structures, and can optionally configure heating, acid addition, alkaline cleaning agent cleaning and other functions.

- What is the difference between GPM and cGMP?

- GMP (Good Manufacturing Practices) is a pharmaceutical production management specification that requires pharmaceutical, food and other manufacturing companies to have good production equipment, reasonable production processes, perfect quality management and strict testing systems to ensure final product quality (including food safety and hygiene etc .) comply with regulatory requirements. cGMP (Current Good Manufacture Practices) is a dynamic pharmaceutical production management regulations that require verification throughout the entire process of product production and logistics, and require companies to use the latest technologies and systems to comply with regulations. GMP is a GMP specification formulated by WHO and applicable to developing countries. It focuses on production hardware, such as production equipment requirements, but the standards are relatively low. cGMP is a GMP implemented in countries such as the United States, Europe, and Japan. It focuses on production software, such as standardizing operator actions and how to handle emergencies in the production process.