- HOME

-

PRODUCTS

Extraction Distillation Equipment Reactor Rotary Evaporator Bioreactor Fermenter Freeze Dryer Spray Dryer Steam Sterilizer Centrifuge Lab Furnace Drying Oven Incubator Low Temperature Freezer Laboratory Equipment Life Science Instrument Drug Testing Instrument Food Testing Instrument Analytical Instrument Petroleum Testing Equipment Water Analysis Instrument

- SOLUTION

- NEWS

- SUPPORT

- VIDEOS

- ABOUT

- CONTACT

20L 30L Jacketed Glass Filtration Reactor For CBD Oil Crystallization

- ModelLCR-20L/30L

- BrandLABOAO

- StockIn Stock

- CustomizedOEM/ODM

- CertificationCE

- Min. Order1 unit

- PortAny port in China

- PackagePlywood case package

DESCRIPTION

The crystallization filter reactor is s a commonly used biochemical instrument, which combines the functions of the reactor and the filter. It suitable for the chemical reaction and physical process under the synthesis, catalysis or other solid liquid of the laboratory / factory, so that one or more steps can be carried out in the same kettle (such as filtration after the completion of the reaction), thus reducing the drift of material measurement and reducing the transfer times of the reaction substrate. It is used in such fields as pharmaceuticals, peptide synthesis, tobacco research and so on.

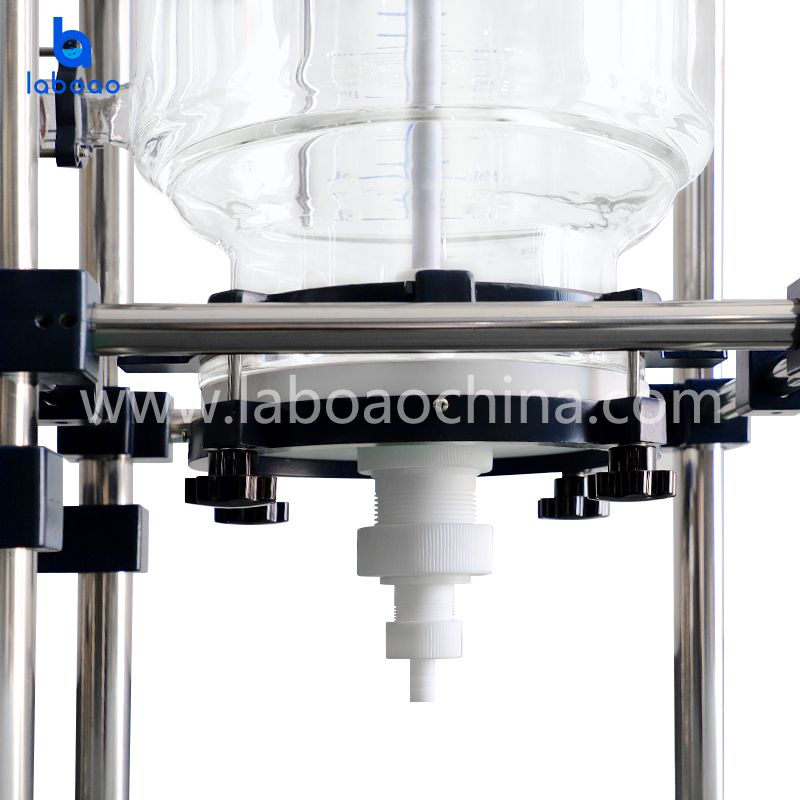

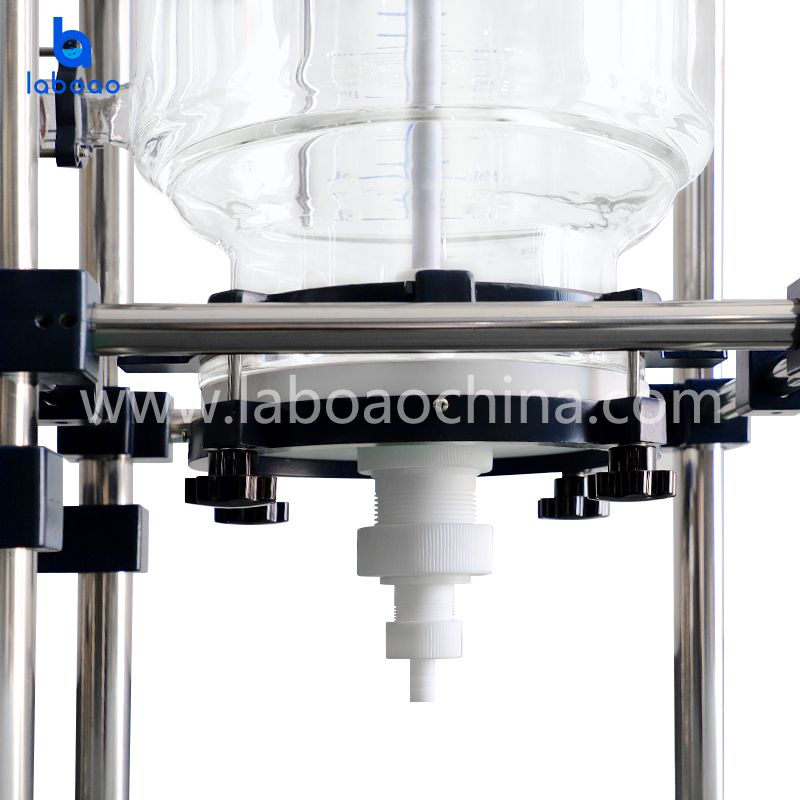

All contact parts are inert and hence allow the same equipment to be used with a wide range of chemicals and solvents . Appropriate filter is used to separate the solid particles of the slurry forming a filtered board. The filtrate drains to the bottom and can be collected from the bottom outlet valve . The filter cake can be easily removed from the bottom to wash PTFE filter.

It’s widely used in pharmaceutical and chemical industries, especially in drug synthesis, fine chemical industry, petrochemical process, new material synthesis, concentration, crystallization and other experiments.

FEATURES

1. The controller box is imported and easy to operate, digital display speed and temperature

2. Option filter plate, pore size from 0.1 to 200μm

3. All glass is GG17 borosilicate glass

4. Filter board can easy removeable

5. PTFE paddle or glass paddle for clients’ option

6. PTFE bottom value with no dead angle design

7. PTFE discharge valve, discharge completely and quickly, no leak/pollution to the solvent.

8. PTFE and special rubber compound seal, can withstand different solvents and maintain high vacuum degree.

9. Stainless steel bracket system, easy to disassemble

10. Customized service according to customers' needs

SPECIFICATIONS

Model | LCR-20L | LCR-30L |

Material capacity | 20L | 30L |

Jacket capacity | 5L | 8L |

Number of lid openings | 6(stir port, temperature measure port, liquid port, solid port, vacuum port, spare port) | |

PTFE mixing paddle | Single layer push type | |

Motor speed | 0-400rpm | |

Speed mode | Frequency | |

Temperature display | Digital Display | |

Discharge valve | PTFE core three-way valve can pass hydrogen | |

Filter chassis | Removable PTFE body | |

Filter plate | Imported material PTFE core | |

Filter diameter | 197mm | |

Sand core aperture | 40-60μm optional | |

Liquid feed valve | PTFE three-way valve | |

Sealing method | Self-lubricating mechanical seal | |

Use environment temperature | 5℃~40℃ | |

Size(L*W*H) | 520*520*1800mm | |

Voltage | 220V/50Hz (can be customized) | |

Optional | 1. Spray device(2 can be used to clean the sign body without dead angle at 360° through negative pressure) 2. Explosion-proof motors 3. Explosion-proof inverter | |

APPLICATION

-

Chemical Synthesis

Chemical Synthesis -

Pharmaceutical Production

Pharmaceutical Production -

Petrochemical Industry

Petrochemical Industry -

Material Science

Material Science -

Material Science

Material Science -

Food and Beverage Industry

Food and Beverage Industry -

Environmental Analysis

Environmental Analysis -

Academic Research

Academic Research

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of crystallization reactor machine.

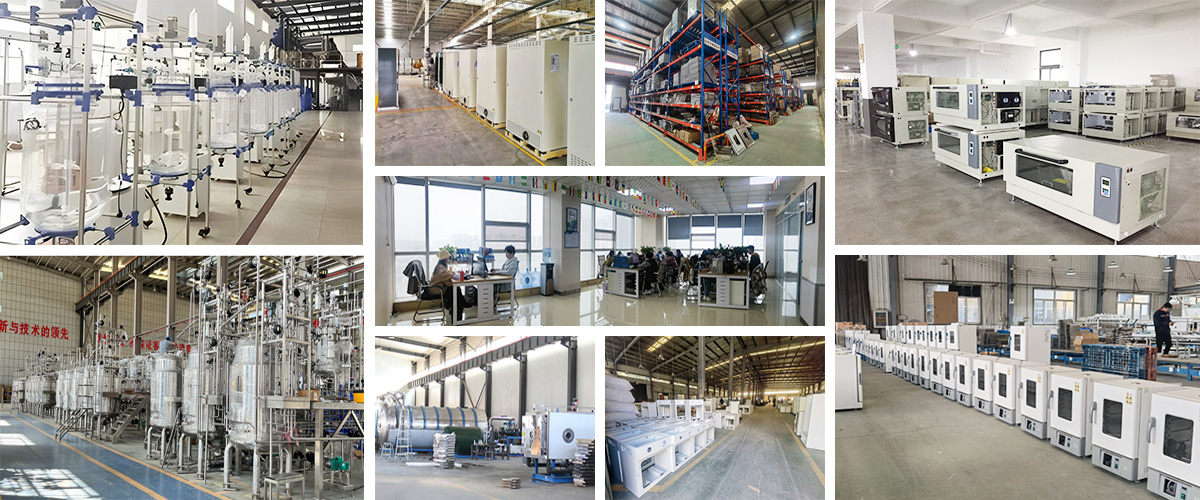

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

PACKAGING & SHIPPING

Our product packaging has been proven over the long term and we usually have plywood boxes or cartons with trays. We will arrange the appropriate packaging according to the weight and size of the goods. Of course, you can also choose the packaging form.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe LABOAO, we grow together!