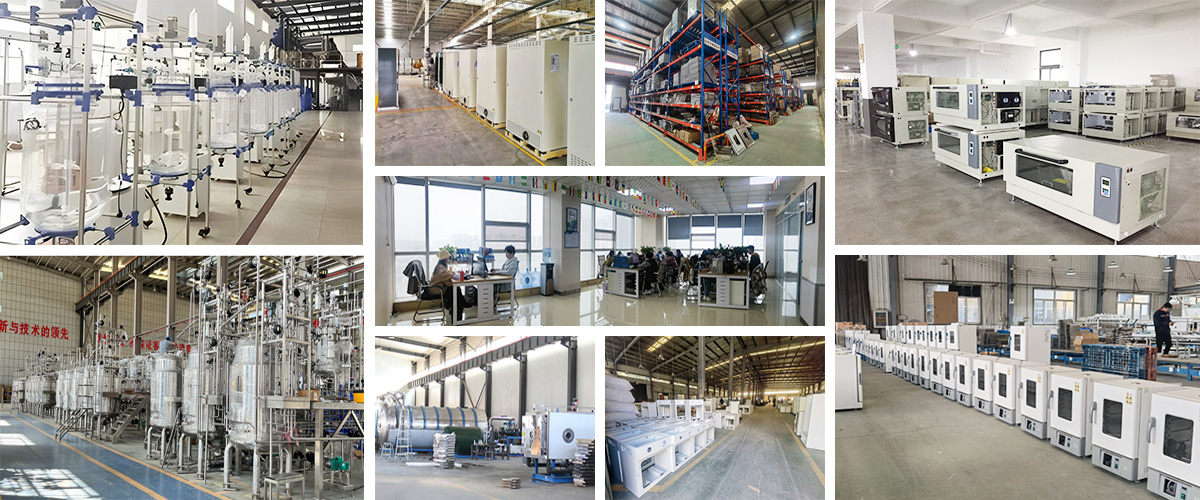

DESCRIPTION

The body of the three-layer glass reactor is composed of two sets of interlayers composed of three layers of glass, which can provide a stirring function and control the evaporation and reflux of the reaction solution. The inner jacket of the three-layer glass reactor is used for heating or cooling. The outer jacket is used for vacuuming, and the refrigerating or heating temperature of the materials in the kettle can be maintained as much as possible under the vacuum state of the outer interlayer. The materials are reacted in the reaction kettle, and after the reaction, the materials are discharged from the PTFE outlet at the bottom of the kettle.