- HOME

-

PRODUCTS

Extraction Distillation Equipment Reactor Rotary Evaporator Bioreactor Fermenter Freeze Dryer Spray Dryer Steam Sterilizer Centrifuge Lab Furnace Drying Oven Incubator Low Temperature Freezer Laboratory Equipment Life Science Instrument Drug Testing Instrument Food Testing Instrument Analytical Instrument Petroleum Testing Equipment Water Analysis Instrument

- SOLUTION

- NEWS

- SUPPORT

- VIDEOS

- ABOUT

- CONTACT

20L Rotary Evaporator With Double Condenser And Receiving Flasks

- ModelLRE-20C1

- BrandLABOAO

- StockIn Stock

- CustomizedOEM/ODM

- CertificationCE

- Min. Order1 unit

- PortAny port in China

- PackagePlywood case package

DESCRIPTION

Rotary evaporator is the use of stepless speed control glass rotating bottle constant speed rotation, the material in the bottle wall to form a large area uniform film, and then by the intelligent constant temperature water bath on the rotating bottle of uniform heating, vacuum conditions, high-speed evaporation, Efficient glass condenser cooling, recovery in the collection bottle.

FEATURES

1. With vacuum controller, can control and display vacuum degree.

2. Double condensers and dual receiving flasks.

3. Can display vapor temperature.

4. With Expansion Column.

5. All PTFE material sealing, with Quick Clamps.

6. Time function, can setting time.

7. USB interface, can download history data.

8. Emergency button for protection.

9. LCD screen display.

SPECIFICATIONS

NO. | ITEM | DETAILS |

1 | 20L rotary evaporator | Distillation rate>10 liter/hr Ethanol |

2 | Dual collection flask | 10L |

3 | Vacuum controller | Display vacuum |

Control vacuum | ||

1 mbar steps for setting | ||

4 | Heating water bath | For 20L flask |

Motorized lifting | ||

5-90 C water temp | ||

Measurement, Accuracy ±1 C | ||

3*2.1kw=6.3 kW | ||

Display temperature | ||

1 ºC steps for setting | ||

5 | Rotation | 5-150 rpm, Soft Start |

adjustable electronically | ||

Accuracy ±1 | ||

ab 0.3kw | ||

Display rotation speed rpm | ||

1 rpm steps for setting | ||

6 | Receiving Flask | 2 * 10 liter |

Disconnecting Valves at top/Bottom, PTFE valve | ||

#1 can be unloaded, while Distillation continue to #2 | ||

7 | Expansion Column | Exist Upstream to Condense |

With vapor temperature sensor | ||

Display Vapor Temperature | ||

1 ºC steps for setting | ||

8 | Condenser | 2 condensers, inparallel manner, Chilled, D2HP configuration |

Connection between glassware is Quick Clamps | ||

each condenser >0.6 m2 | ||

Vacuum is at bottom Condensers | ||

9 | Material | MOC: SS304/SS316 |

Glass: Borosilicate 3.3 | ||

In Contact with Product: PTFE | ||

10 | Other request | With timer function |

Leakage of complete System: <1mbar/min | ||

With Process Data Recording function, USB interface | ||

With air switch for emergency button | ||

Over-Pressure protection |

APPLICATION

-

Chemical Laboratories

Chemical Laboratories -

Pharmaceutical Industry

Pharmaceutical Industry -

Essential Oil Extraction

Essential Oil Extraction -

Cannabis Industry

Cannabis Industry -

Food and Beverage Industry

Food and Beverage Industry -

Environmental Analysis

Environmental Analysis -

Academic Research

Academic Research

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of automatic lifting rotary evaporator machine.

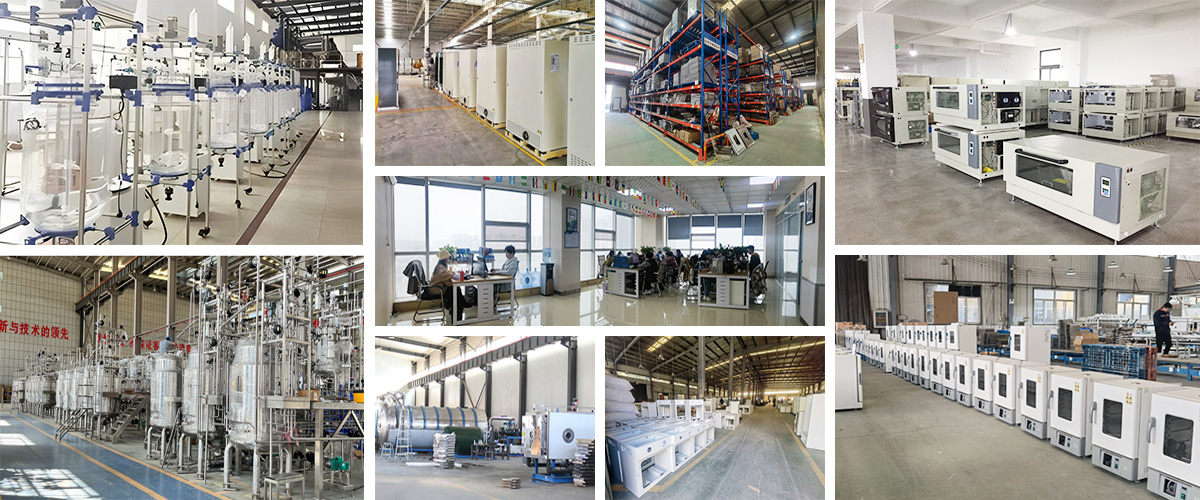

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

PACKAGING & SHIPPING

Our product packaging has been proven over the long term and we usually have plywood boxes or cartons with trays. We will arrange the appropriate packaging according to the weight and size of the goods. Of course, you can also choose the packaging form.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe LABOAO, we grow together!