- HOME

-

PRODUCTS

Extraction Distillation Equipment Reactor Rotary Evaporator Bioreactor Fermenter Freeze Dryer Spray Dryer Steam Sterilizer Centrifuge Lab Furnace Drying Oven Incubator Low Temperature Freezer Laboratory Equipment Life Science Instrument Drug Testing Instrument Food Testing Instrument Analytical Instrument Petroleum Testing Equipment Water Analysis Instrument

- SOLUTION

- NEWS

- SUPPORT

- VIDEOS

- ABOUT

- CONTACT

CM10 Series Coating Thickness Gauge

- ModelCM10 Series

- BrandLABOAO

- PortAny port in China

- PackagePlywood case package

DESCRIPTION

A thickness gauge is a precision instrument used for accurately measuring the thickness of materials or objects. It utilizes technologies such as ultrasound, laser, eddy current, X-ray, or mechanical contact to achieve non-destructive or contact-based measurements ranging from nanometers to centimeters. Its main applications include quality control and process monitoring in fields such as automotive manufacturing, metal processing, aerospace, construction engineering, and industrial corrosion prevention.FEATURES

1. High-precision measurement: Features micron-level or higher measurement accuracy, ensuring the accuracy of coating thickness data.

2. Non-destructive testing technology: Employs non-destructive measurement methods, preserving the integrity of the coating and substrate.

3. Multi-substrate compatibility: Supports coating measurement on various substrate surfaces, including metal, plastic, and wood.

4. Intelligent calibration function: Allows for automatic or manual calibration to adapt to different measurement conditions and standards.

5. Portable and easy-to-operate design: Lightweight handheld device with an intuitive interface, suitable for quick on-site testing.

6. Data storage and transmission: Built-in storage space, supporting data export via USB, Bluetooth, or wireless connection.

7. Strong environmental adaptability: Some models feature dustproof, oil-proof, and electromagnetic interference resistance, suitable for industrial environments.

8. Multiple probe options: Equipped with probes based on different principles (e.g., magnetic induction, eddy current, ultrasonic) to handle complex surface structures.

9. Real-time display and alarm: Measurement results are displayed in real time, and thresholds can be set for out-of-range alerts.

SPECIFICATIONS

Model | CM10F | CM10FH | CM10N | CM10FN | |

Measuring Principle | Magnetic Method | Magnetic Method | Eddy Current Method | Magnetic and eddy current integration | |

Measuring Range(μm) | 0-3000 | 0-10000 | 0-2000 | 0-1500 | |

Low Range Sensitivity(μm) | 0.1 | 0.1 | 0.1 | 0.1 | |

Tolerance(μm) | ±(2%H+2) | ±(2%H+10) | ±(2%H+2) | ±(2%H+2) | |

Testing Condition(mm)) | Min.Curvature Radius | 5 | 10 | 5 | 5 |

Min.Area Diameter | Φ20 | Φ40 | Φ20 | Φ20 | |

Min. Substrate | 0.5 | 2 | 0.5 | 0.5 | |

Display | High Contrast Segment Liquid Cstal Display (LED Backlight) | ||||

Statistics | N,MAX,MIN,MEAN and STD.DEV | ||||

Calibration | One-Point Calibration and Two-Point Calibration | ||||

Working Temperature | -10° C to +50 °C-20°C in special requirement | ||||

Auto Power- | Auto off after 3 minutes of inactivity | ||||

Power | Two 1.5V AA batteries,low-voltage indication function | ||||

Weight | 200g including batteries | ||||

Size | 149mm*73mm*32mm (H*W*D) | ||||

Standard Configurations | |||||

CM10 Coating Thickness Gauge | Probe (integrated with instrument) | ||||

Zero Plate | Calibration Foils | ||||

Carrying Case | Operating Manual | ||||

Certification of Quality,Packaging List | USB Communication Cable | ||||

Communication CD | |||||

Optional Configurations | |||||

Calibration Foils | Fe Zero Plate | ||||

AI Zero Plate | |||||

WHY CHOOSE US

- Factory direct sales with competitive price.

- Premium quality with CE & ISO certification.

- Strong product OEM & ODM customization capability.

- Promise production & on-time delivery.

- Perfect after-sales service, free product accessories.

- 15 years of experience in R&D and production of ultrasonic thickness gauge machine.

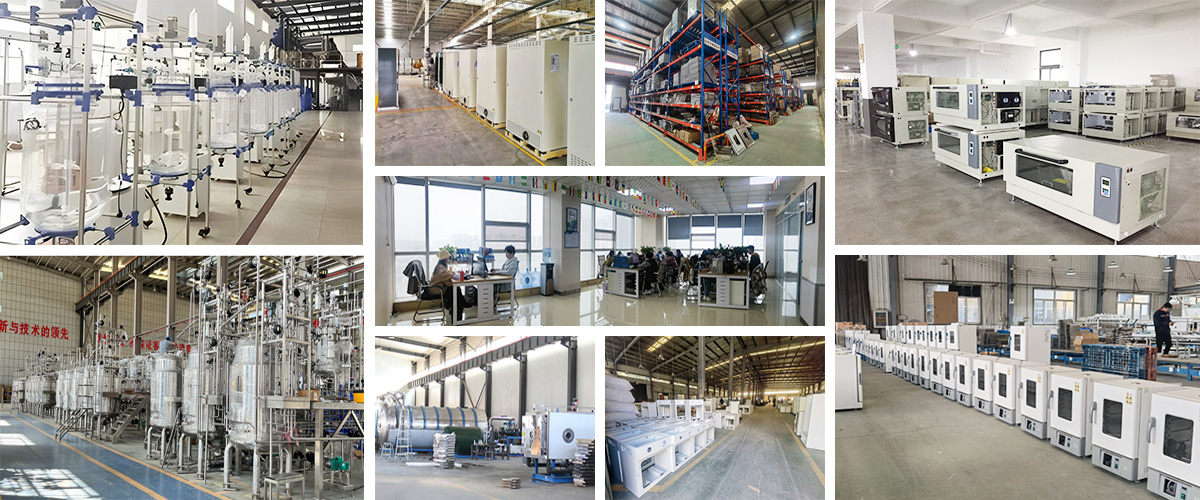

OUR FACTORY

We have a standard production workshop and a complete production team. They always produce a serious and responsible attitude to produce each product. Our R&D team is made up of multi-aspects professional engineers such as design engineer,technology specialist ,qualified specialist and process control manager, etc. Our qualified specialists strictly realize the process comprehensive supervision based on our quality process control system, which contains products design, research and development, test, production, quality inspection and packaging.

PACKAGING & SHIPPING

Our product packaging has been proven over the long term and we usually have plywood boxes or cartons with trays. We will arrange the appropriate packaging according to the weight and size of the goods. Of course, you can also choose the packaging form.

CUSTOMER CASES

Our laboratory instruments and equipment are used in many scientific laboratories, scientific research institutions, universities, hospitals, centers for disease control and other institutions, and are combined with many well-known biopharmaceuticals, new energy, electronics companies, food processing, environmental protection, etc. Enterprise cooperation, our stable and reliable products are exported to more than 120 countries around the world, and have been highly recognized by them, believe LABOAO, we grow together!